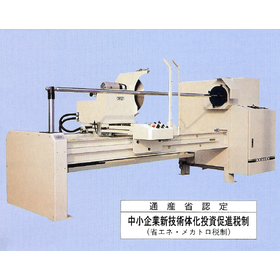

Semi-Automatic Roll Cutter "CM-330S"

Easy operation with one touch! Excellent economy, efficiency, and heat resistance to accommodate various materials!

The "CM-330S" is a semi-automatic roll cutter (double-edged grinding machine) that uses borazon grinding wheels, offering excellent economy, efficiency, and heat resistance. The rotation of the cutter and chuck is infinitely variable through inverter control. The shaft is custom-made to fit paper tubes, ensuring there is no rotational wobble of the raw material. In addition to adjusting the grinding angle and position, the operation of the shaft indicator rod and the replacement of the chuck's outer claws can be done with a single touch. The operation switches are centralized at the operator's hand, and the cutting dimensions can be easily input via a touch panel. Furthermore, it is equipped with safety features that automatically stop the machine if an abnormal load is detected on the cutter or chuck. 【Features】 ■ Excellent economy (long-lasting durability) ■ Excellent efficiency (reduced grinding time, less prone to clogging) ■ Excellent heat resistance (capable of long grinding sessions) ■ Various adjustments and operations can be performed with a single touch ■ Double and triple safety measures ★ We also accept online meetings (Skype) at any time, so please feel free to contact us. * For more details, please refer to the catalog or feel free to inquire.

- Company:コルテック

- Price:Other